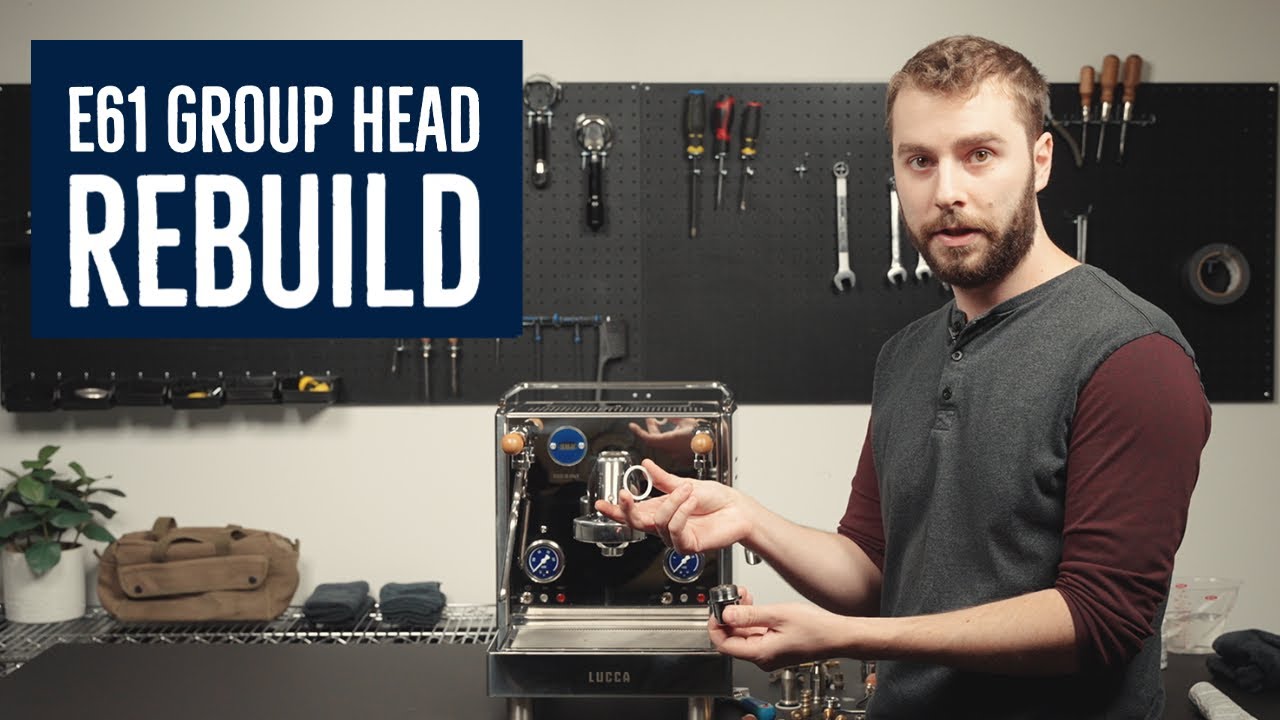

Hi there, I’m Zach, a tech manager at Clive Coffee. Today, let’s dive into the E61 group head rebuild on the M58 espresso machine. If you’re a coffee enthusiast owning an E61 machine, this procedure is crucial for maintaining optimal performance over the years. Typically, this rebuild is part of a three to five-year maintenance plan. However, the exact timeline may vary based on your water quality and usage. Through years of experience, we’ve pinpointed the components commonly in need of replacement: the camshaft, pre-infusion valve, top brew valve, drain valve, camshaft gaskets (two of them), a Teflon cap, three large Teflon gaskets, and the E61 cap filter.

The process begins with disassembling the mushroom assembly. This step simplifies the entire procedure as it removes tension from the valve system, making it easier to handle. Start with two wrenches to loosen the top cap, and soon enough, you’ll be able to unscrew it by hand. Inside, you’ll find the E61 filter screen. A pair of tweezers can help lift it out. Often, the declaimer, a small component with an easy-to-clog tiny hole, should be soaked as well. Moving forward, the top brew valve and spring are taken out, revealing worn gaskets that differentiate used components from new, shiny brass ones. Ensuring there’s no tension in the brew lever is key before proceeding with further disassembly, especially with components under significant spring pressure.

Disassembling the Mushroom Assembly

To kick things off, we remove the mushroom assembly. This initial step is crucial as it reduces the tension from the internal springs, making the entire process more approachable. Use two wrenches—one on the top and one on the bottom—to break the cap loose. Once it’s loosened, you can unscrew it by hand. Inside, you’ll find the E61 filter screen, which can be lifted out with a pair of tweezers. It’s also a good idea to soak the declaimer since it can easily get clogged.

Next, it’s time to remove the mushroom housing assembly. Use a wrench to break it loose, and to avoid scratching the stainless steel, ensure the wrench fits perfectly or use masking tape or a towel. Inside the housing, you’ll find the top brew valve and spring. These components may appear discolored and worn out, and their gaskets will indicate the extent of usage. Lifting the brew lever removes internal spring tension, which is essential before proceeding further with the disassembly.

Handling the Pre-Infusion and Drain Valves

Once the mushroom assembly is out, you’ll find the pre-infusion valve and spring inside. This assembly also contains a small cap piece holding the spring in place. You have multiple options for disassembling the drain valve. Use two wrenches on opposite sides to apply counter force, breaking it loose. Once free, you’ll find another spring and drain valve inside.

Next, remove the brew lever to access the camshaft assembly. This involves unscrewing a small assembly with a flat blade. Inside, you’ll find a crush washer and spring, which are quite heavily loaded. Removing the brew lever provides you with access to the camshaft gaskets, ensuring that all internal components are easily reachable for replacement and cleaning.

Accessing the Camshaft Assembly

To reach the camshaft and its gaskets, first remove the outside fitting using two wrenches. This action will release a spring and a small stem valve, pressing against the camshaft gaskets. Afterward, remove the rest of the camshaft assembly with an adjustable wrench. Inside, you’ll find the camshaft valve and the gaskets that need replacement.

Once the components are removed, soak them in hot water mixed with a cleaning solution like Cafiza to get rid of any grime. This ensures that every part is clean before reassembly. Using a dental pick can help remove stubborn gaskets from their slots, ensuring that the new ones fit perfectly.

Reassembling the Components

Begin reassembly by inserting the new camshaft gaskets, applying a small amount of Molykote to them for better sealing and longevity. The camshaft valve also benefits from this lubricant, as it eases insertion and ensures smooth operation. Reinstall the camshaft valve into the E61 assembly, keeping the brew lever in the down position to ensure proper alignment.

Next, tackle the spring assembly and the valve that presses against the camshaft gaskets. Once in place, install the brew lever back into its original position. Confirm its functionality by observing the movement within the mushroom assembly as you manipulate the lever.

Final Steps and Testing

Reassemble the E61 assembly by first installing the top brew valve and spring. Apply Molykote to the gasket and spring for optimal performance. Reinstall the mushroom assembly, ensuring all components are aligned and the spring tension is correct. Once assembled, use an adjustable wrench to secure all parts.

Before reinstalling the pre-infusion chamber, make sure the old Teflon gasket is removed to avoid stacking issues. Reinsert the pre-infusion valve, spring, and cap piece, making sure to use Molykote for lubrication. With the brew lever lifted, reinstall the drain valve by pressing against the spring and starting the threading by hand. Use an adjustable wrench for final tightening.

Once everything is back in place, perform a cold backflush to check for leaks. Insert a portafilter with a backflush disc, turn the machine on, and lift the brew lever to build pressure. If there are no leaks, your E61 rebuild is successful.

The E61 rebuild process is an essential task for maintaining the performance and longevity of your espresso machine. By diligently following each step, coffee enthusiasts can ensure their M58 machine remains in peak condition for years to come.

Starting with the disassembly of the mushroom assembly to reduce spring tension, and continuing through the careful removal and soaking of various valves and gaskets, every step is crucial. The use of tools like wrenches and dental picks, along with lubricants like Molykote, ensures smooth reassembly and optimal performance.

After reassembly, conducting a cold backflush test is key to identifying any leaks and confirming that each component has been correctly installed. By following these detailed instructions, users can confidently perform an E61 rebuild and enjoy consistent, high-quality espresso from their M58 machine.